Michigan Maple Block Company, located in Petoskey, Michigan—the heart of hard maple country—is one of the largest and oldest manufacturers of butcher block products in the nation. The success and renown of its Wood Welded® butcher block is due in part to its continuous operation, by one family, for over 125 years.

End-grain laminated hard maple butcher block was developed as the practical answer to the needs of the meat cutting industry over 100 years ago. The harder, close grained, less porous cutting surface of laminated butcher block quickly replaced the sycamore rounds, which were the meat cutting surface of the day. Even today, hard maple butcher block remains the preferred preparation surface because of its durability and ease of maintenance.

In the early 1880’s, Petoskey was a small working village at the end of Little Traverse Bay in northwestern Lower Michigan. The lumber industry was booming, and on the nearby Bear River, two businessmen, Mr. Baker and a Mr. Forbes, founded a woodenware manufacturing plant. After a few short years they sold the business to Frank and Fred Bauerle, who ran it until the turn of the century.

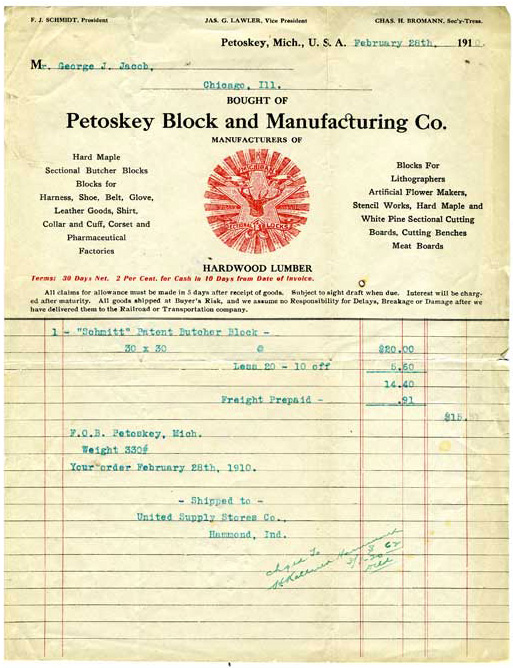

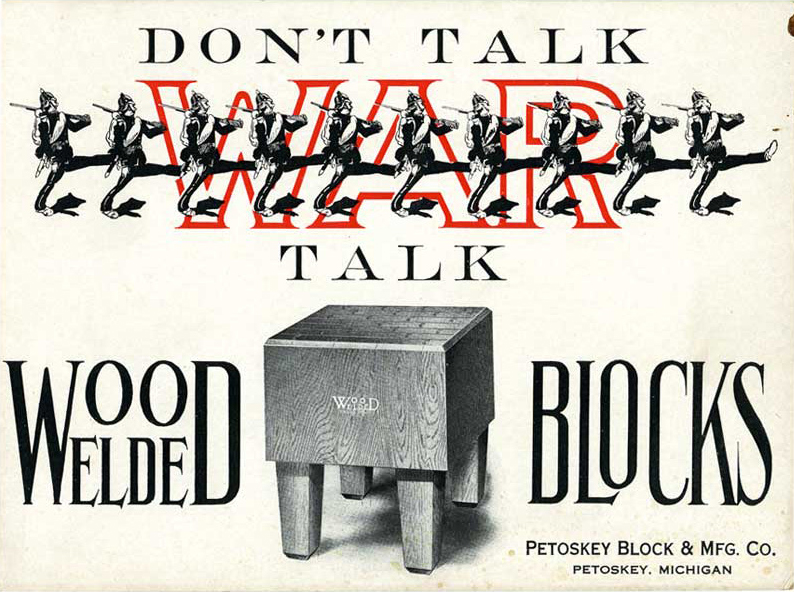

Then two Chicago businessmen with ties to the meat cutting industry, Charles H. Broman and Frederick J. Schmitt, recognized the problems inherent in the standard meat cutting block of the day, a log section of southern sycamore. Not only did sycamore split as it dried, but the size of the cutting surface was limited by the size of the log. Schmitt and Broman determined that laminated hardwood is the answer to a better meat cutting surface. Broman bought out the Bauerle brothers to begin manufacturing, while Schmitt traveled the country as the national sales representative.

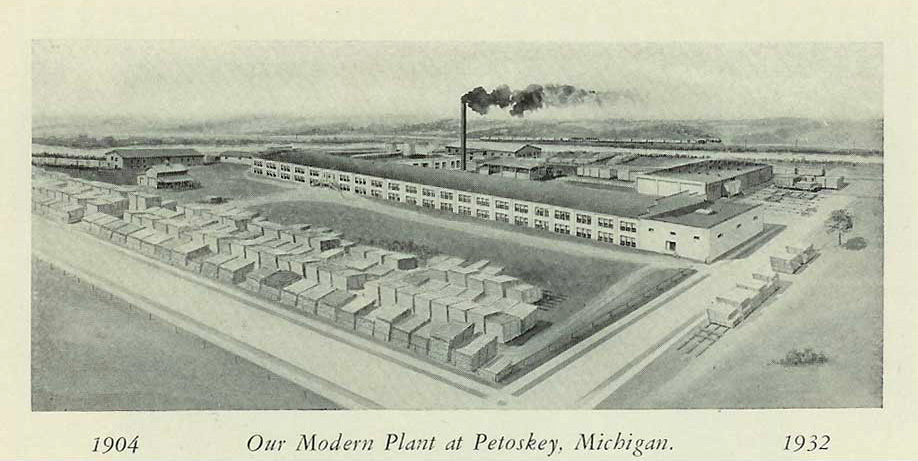

The new company, known as The Petoskey Block and Manufacturing Company, invested in timberlands and purchased cut lumber from local sawmills. They built their own sawmill on the factory’s 13-acre site and constructed enormous dry kilns powered with the hot air supplied by burning the plant’s scrap wood and sawdust.

By 1903, Schmitt had become the company’s majority stockholder. He refined the appearance of the butcher block, making many design improvements. From 1907 through 1916 he obtained several patents for his “Butcher’s Chopping Block” and most importantly for his technique of laminating, known today as the “Wood Welded” process.

![HistoryHeader2[1]](https://butcherblock.com/wp-content/uploads/2023/02/HistoryHeader21.jpg)